If you’ve encountered the term “3000gf” and felt a bit puzzled, you’re not alone. At first glance, it might seem like just a random collection of letters and numbers. But in reality, it’s a designation that carries specific technical meaning, primarily in the realms of physics and engineering. In this blog post, we’ll take a deep dive into what “3000gf” means, its applications, and why it’s important in various industries.

Let’s start by breaking down the term itself.

- What Does “3000gf” Stand For?

“3000gf” is an abbreviation for 3000 gram-force. To fully understand this, we need to define “gram-force.” A gram-force (gf) is a unit of force that indicates the amount of force exerted by a mass of one gram under standard gravity. Essentially, it’s a measure of the force that gravity applies to a one-gram object.

In the case of “3000gf,” this simply means the force equivalent to 3000 grams under standard gravity. To put it in perspective:

1 gf = 1 gram × standard gravity (9.80665 m/s²).

Therefore, 3000gf = 3000 grams × standard gravity.

The concept of gram-force is similar to the more familiar Newton, which is the standard unit of force in the International System of Units (SI). While gram-force is often used in more specialized contexts, understanding its relationship to other units of force is crucial:

1 gf = 0.0098 Newtons (approximately).

3000 gf = 3000 × 0.0098 = 29.4 Newtons.

This gives us a sense of the magnitude of 3000gf in terms of a more commonly used unit like the Newton.

2. Why Is “3000gf” Used?

The use of “3000gf” or gram-force as a unit of measurement might seem redundant when we have more universal units like the Newton. However, gram-force is still widely used in industries and applications that require a simpler, more intuitive way of measuring force. For instance, in fields like material testing, component design, or even ergonomics, using gram-force can make measurements and results more relatable and easier to communicate, especially when the masses involved are small.

In particular, “3000gf” is a common specification in industries that deal with lightweight materials or delicate components. Let’s look at some of the specific applications where you might encounter 3000gf as a measurement.

3. Applications of “3000gf” in Various Industries

The concept of 3000gf is used in multiple contexts, from engineering and product testing to ergonomics and material science. Here’s how it’s applied in different fields:

a. Engineering and Product Design

In product design, particularly for small devices like electronics or mechanical parts, specifying force in gram-force rather than Newtons can provide a clearer understanding of stress, tension, and operational limits. For example, in the design of switches, levers, or buttons, the amount of force required to activate a component is often measured in gf. A button might require 3000gf to be pressed, ensuring it’s neither too easy to activate accidentally nor too difficult for the user.

b. Material Testing and Quality Control

In quality control and material testing, 3000gf is often used as a benchmark for tensile strength, compression, or shear testing. For instance, a wire might be tested to ensure it can withstand 3000gf of tensile force before snapping. By using gf, the measurement relates more directly to the weight of a known mass (like 3000 grams) being applied to the material, making it easier to visualize and compare.

c. Ergonomics and Biomechanics

Ergonomists often use gf measurements when studying the strength and comfort levels of human interaction with devices. For instance, determining the appropriate grip strength for a hand tool might involve ensuring that the force required does not exceed 3000gf, which might be beyond comfortable limits for certain user groups.

In biomechanics, forces applied by muscles or joints are sometimes expressed in gf, making it easier to relate to everyday experiences. For example, lifting an object that exerts a force of 3000gf is analogous to lifting a weight of 3000 grams (or 3 kilograms), providing a straightforward understanding of effort and strain.

d. Adhesives and Bonding Strength

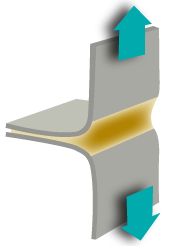

In the manufacturing industry, the force required to separate bonded materials (like adhesives or tapes) is often measured in gf. A bond that withstands up to 3000gf before breaking can be a crucial specification for ensuring durability and performance, especially in automotive or aerospace applications where reliable adhesion is critical.

4. The Science Behind “3000gf”: Calculating and Understanding Forces

To better understand what 3000gf actually means in a practical context, it’s helpful to consider the physics behind it. As mentioned, gram-force is tied directly to the concept of gravity. Let’s break it down:

The formula to calculate gram-force is:

\text{gf} = \text{mass (in grams)} \times \text{acceleration due to gravity (9.80665 m/s}^2\text{)}

Thus, 3000gf is equivalent to a force of:

3000 \times 9.80665 = 29419.95 \text{ dynes}

or approximately 29.42 Newtons. This might seem like a large number, but in practice, it’s about the same force you’d experience when holding a 3-kilogram object (like a bag of flour) in your hand. This helps contextualize the magnitude of the force in day-to-day terms.

5. Converting “3000gf” to Other Units of Force

If you need to convert 3000gf to other units of force, such as pounds-force (lbf) or Newtons, it’s quite straightforward:

Newton (N): As noted earlier, 1 gf = 0.0098 N. Therefore, 3000gf = 29.4 N.

Pound-force (lbf): 1 gf = 0.0022 lbf. Therefore, 3000gf = 3000 × 0.0022 = 6.61 lbf.

This means that a force of 3000gf is approximately equal to 6.61 pounds-force, or about the weight of a typical handheld object like a large textbook.

6. The Importance of 3000gf in Product Specifications

When you see a specification that lists 3000gf as a requirement, it’s not just an arbitrary number. It’s a carefully chosen force threshold that ensures the product will perform correctly under specified conditions. This could be the activation force for a mechanical switch, the maximum force a bonded surface can withstand, or the amount of pressure a material can bear before deforming.

For example, consider a tactile switch in a keyboard. If the switch requires 3000gf to activate, it means that it’s designed to respond only to deliberate presses, providing tactile feedback without being too sensitive. Such specifications are crucial for both usability and durability.

Similarly, in testing adhesives, a specification of 3000gf might be used to determine the peeling strength of a tape. A tape that withstands 3000gf without coming off is much more suitable for high-stress applications compared to one that peels off under lighter forces.

7. Practical Implications of Understanding “3000gf”

Knowing the meaning of 3000gf can be incredibly useful when evaluating product specifications, conducting experiments, or analyzing forces in both personal and professional contexts. For engineers and designers, it provides a common language for describing forces that are too small to comfortably express in larger units like Newtons or pound-force.

Furthermore, being able to conceptualize and calculate gram-force can aid in troubleshooting and optimization. If a component consistently fails under a 3000gf load, understanding the exact amount of force involved allows for precise modifications—whether that means choosing a stronger material or adjusting the load distribution.

8. Final Thoughts: Why “3000gf” Matters

In summary, “3000gf” is more than just a unit of measurement. It’s a precise, relatable way to communicate forces in contexts where using Newtons or pound-force might seem abstract. Whether you’re working in product design, material testing, or ergonomics, understanding the concept of gram-force can help you make informed decisions and better understand specifications.

The next time you come across a force requirement like “3000gf,” you’ll know that it refers to a very specific amount of force, equivalent to what you’d experience when holding a 3-kilogram object under standard gravity. It’s a small unit that plays a big role in ensuring the safety, usability, and performance of countless products and materials around us.

By embracing units like 3000gf, we gain a clearer picture of the forces at play, making it easier to design, evaluate, and refine the world around us with precision and confidence.

1 thought on “Understanding the Concept of “3000gf” and Its Meaning”